Extends the life of contaminated reinforced concrete.

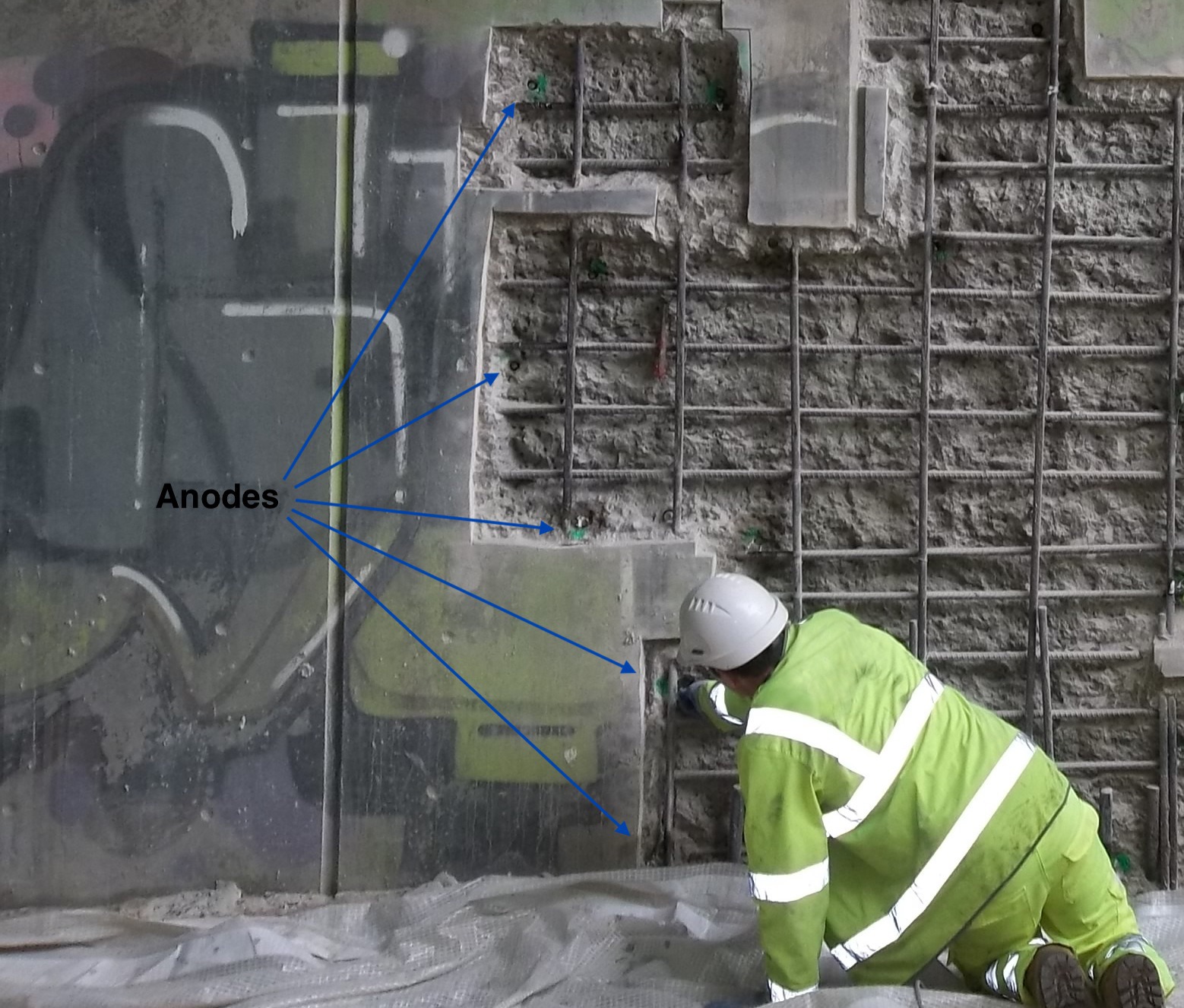

PatchGuard™ anodes extend the life and area of Patch repairs. Our PatchGuard™ galvanic anodes redress the electrochemical imbalance induced through removal of contaminated concrete in patch repairs, commonly known as the Incipient Anode Effect. PatchGuard™ anodes corrode preferentially to the surrounding steel – protecting it from further corrosion damage.

PatchGuard™ combats the two main types of corrosion found in reinforced concrete structures.

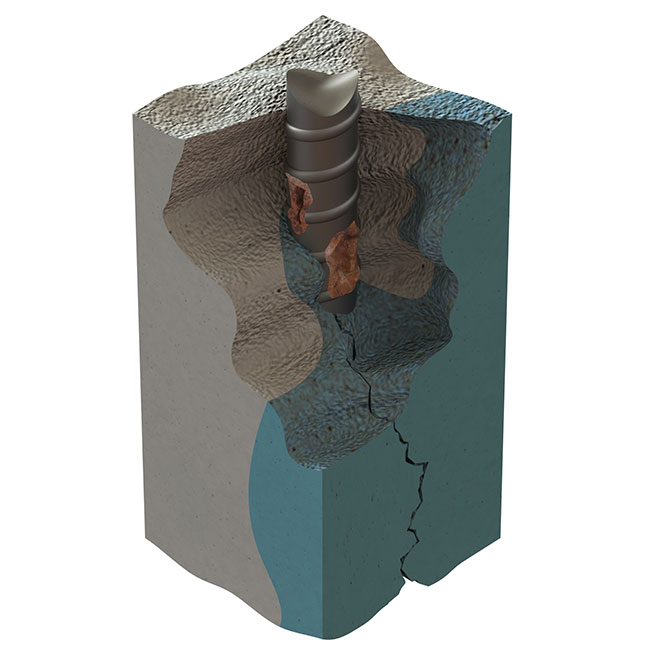

Carbonation induced – exposure to atmospheric carbon dioxide combined with prolonged contact to sufficient moisture and oxygen can leave steel vulnerable to corrosion.

Chloride induced – if chloride in the form of inherently mixed set accelerators or external aggressive salts permeates reinforced concrete in sufficient quantities, an aggressive form of corrosion can be initiated.

When either or both of these take hold in a structure, this can lead to the concrete cracking and being displaced as the steel reinforcement expands. The corrosion and its effects often propagate very quickly, so it is crucial to be proactive in assessing and fixing the issue to protect the structure and maintain its asset value.

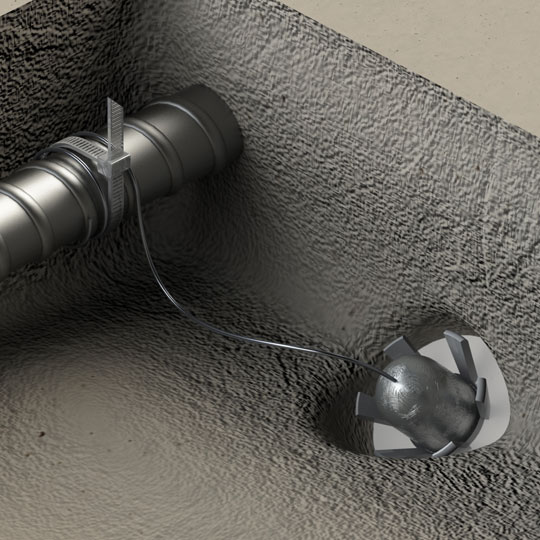

PatchGuard™ counters corrosion adjacent to the patch following patch repair but unlike traditional sacrificial anodes it is installed at the perimeter of the patch repair into the parent concrete. This significantly improves the ionic current flow from the anode through the concrete material as the parent concrete is less resistive compared to repair mortars, making the PatchGuard™ anode more efficient than traditional sacrificial anodes.

The full package: CPT also supplies all the ancillary materials needed for PatchGuard™ installation, including embedding mortar and attachment materials.

Anodes are available in 5 sizes to suit any structure:

PatchGuard™ 100: 32 mm long x 18 mm diameter

PatchGuard™ 175: 42 mm long x 18 mm diameter

PatchGuard™ 350: 77 mm long x 18 mm diameter

PatchGuard™ 400: 95 mm long x 18 mm diameter

PatchGuard™ 500: 110 mm long x 18 mm diameter

PatchGuard™ is also available as an inter-connected system for installation outside patch repairs.

For more information, visit the PatchGuard™ Connect page here.

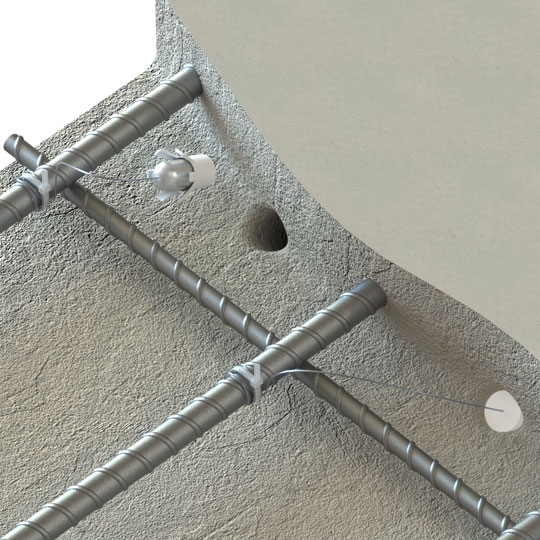

PatchGuard™ anodes are installed into the perimeter of patch repairs through the breakout area into pre-drilled 25mm diameter holes at around 400mm centres. The holes are grouted with our pre-mixed DuoCrete PG™ embedding mortar pre-installation.

After the PatchGuard™ anodes have been inserted into the holes they are tied to the steel using the attached titanium connecting wire and the holes are capped using a standard repair mortar. Concrete repairs can then be carried out at any time after anode installation. If the repairs are carried out within two hours it is not necessary to cap off the anode holes.

Rather than the traditional approach of attaching galvanic anodes to exposed steel in the patch repair, PatchGuard™ anodes are located within the surrounding unrepaired concrete. Protective current is delivered directly to the steel outside the patch repair – which is at greatest corrosion risk as opposed to the clean steel within the patch repair.

As PatchGuard™ is positioned within the host concrete, there is no compromise in the quality of the concrete repair material used in reinstatement, as is typically the case for sacrificial anodes placed within patch repairs.

Individually connected galvanic anode for patch repairs – MCHW Type 1b