RebaGuard™ is a discrete anode for new build and repair applications.

RebaGuard™ combats the two main types of corrosion found in reinforced concrete structures.

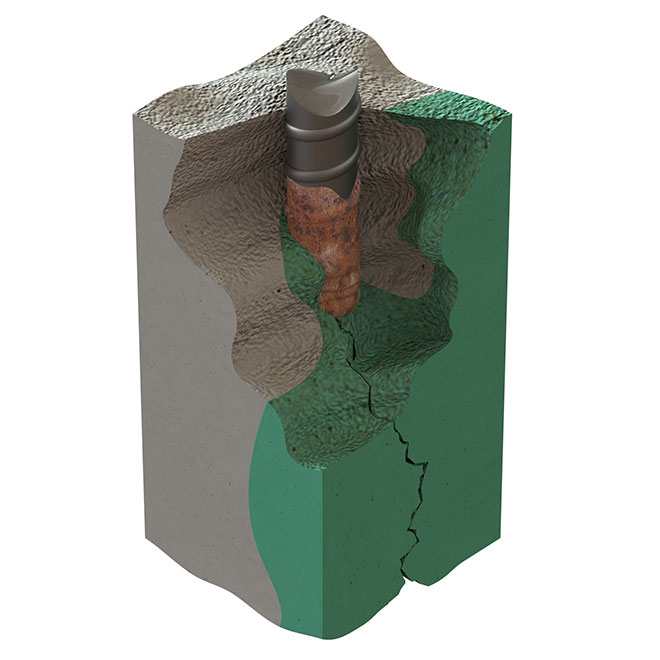

Carbonation induced – exposure to atmospheric carbon dioxide combined with prolonged contact to sufficient moisture and oxygen can leave steel vulnerable to corrosion.

Chloride induced – if chloride in the form of inherently mixed set accelerators or external aggressive salts permeates reinforced concrete in sufficient quantities, an aggressive form of corrosion can be initiated.

When either or both of these take hold in a structure, this can lead to the concrete cracking and being displaced as the steel reinforcement expands. The corrosion and its effects often propagate very quickly, so it is crucial to be proactive in assessing and fixing the issue to protect the structure and maintain its asset value.

RebaGuard™ is a discrete galvanic anode applied to reinforcing steel in new structures, re-cast structural elements and concrete patch repairs. For any structure, suffering expansive reinforcement corrosion and spalling, local concrete repairs often lead to incipient corrosion damage known as the halo or ring anode effect. RebaGuard anodes corrode preferentially to the surrounding steel, within the zone of influence, mitigating the risk of rebar corrosion.

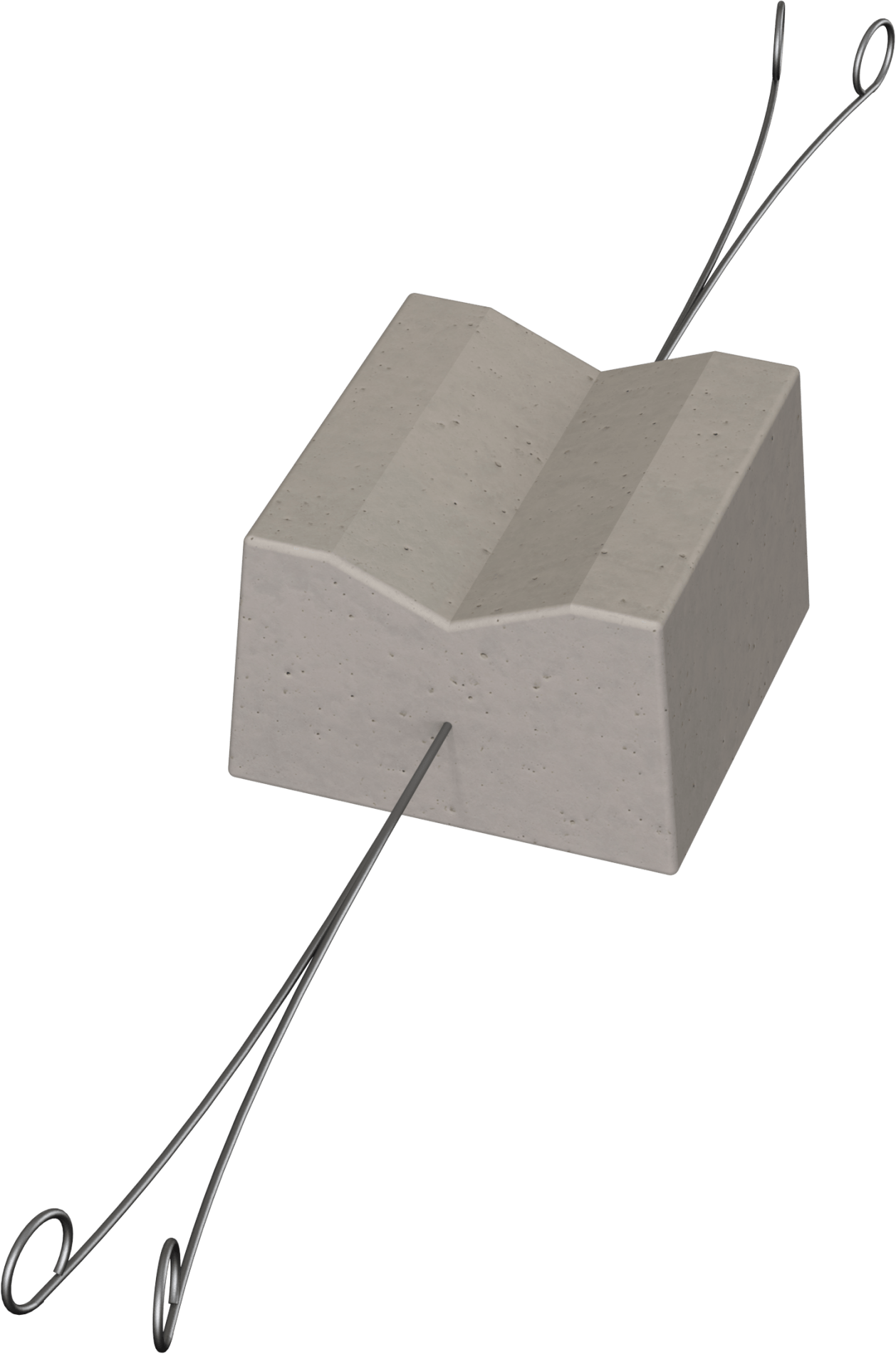

Anodes are available in 3 sizes to suit any structure:

RebaGuard™: 55mm x 55mm x 35mm

RebaGuard™ Plus: 75mm x 55mm x 35mm

RebaGuard™ Ultra: 70mm x 60mm x 35mm

In new-builds, the pre-soaked RebaGuard™ anodes are attached to the reinforcing cage prior to concrete pour. In existing structures, the soaked RebaGuard™ anodes are installed at the edge of the concrete repairs and attached alongside or beneath the rebar using the integral corrosion resistant tie wires.

Where the repair mortar has a high resistivity, in excess of 15,000 ohm-cm, the RebaGuard™ anodes should be encapsulated in a low resistivity bridging mortar.

The RebaGuard™ anodes corrode sacrificially over the course of their design life safeguarding the structure from the effects of reinforcement corrosion.

Galvanic Anode