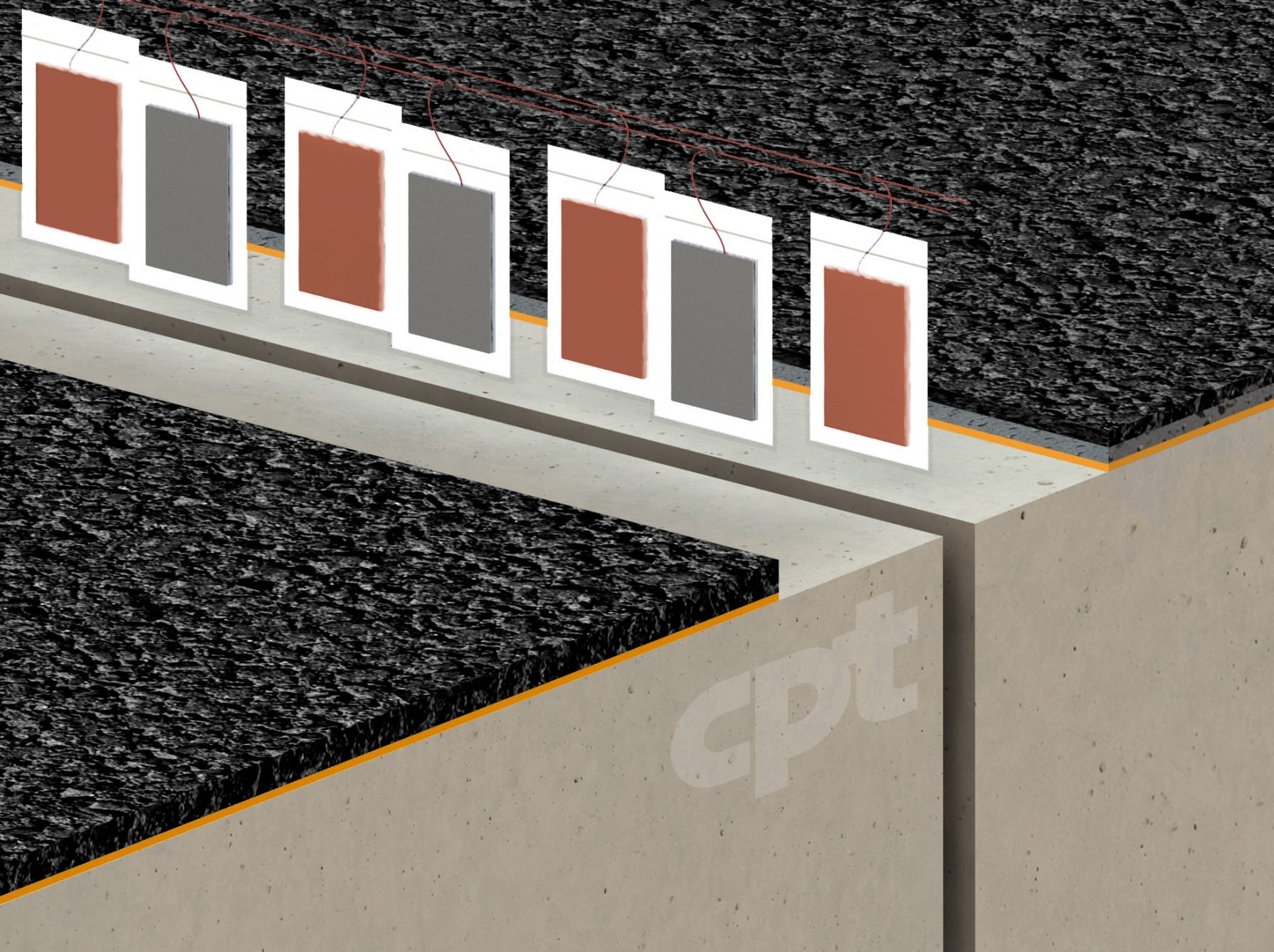

Our unique ProtectorJoint™ system is designed to be installed into existing joints or gaps between structural elements, delivering powerful long-term corrosion protection to adjacent steel reinforcement.

Reinforcing steel around expansion joints or bearing shelves is often heavily congested and difficult to access. If chloride contaminated water enters the joint and soaks the concrete, corrosion can occur resulting in loss of steel section along with cracking and spalling of the concrete cover.

Half-joints in bridge decks are of particular concern as contaminated water can collect on the shelf at the centre of the joint and permeate the structure to adversely affect the critical steel around the joint – including the diagonal bars running top to bottom on the cantilevered span.

Anodes designed to control corrosion of deeply buried steel have typically been placed into holes drilled from the surface. Depending on the size and configuration of reinforcing bars this can be difficult to achieve without hitting steel. Even if holes are successfully drilled between the bars there is an increased risk of shorts in the system where anode material touches steel.

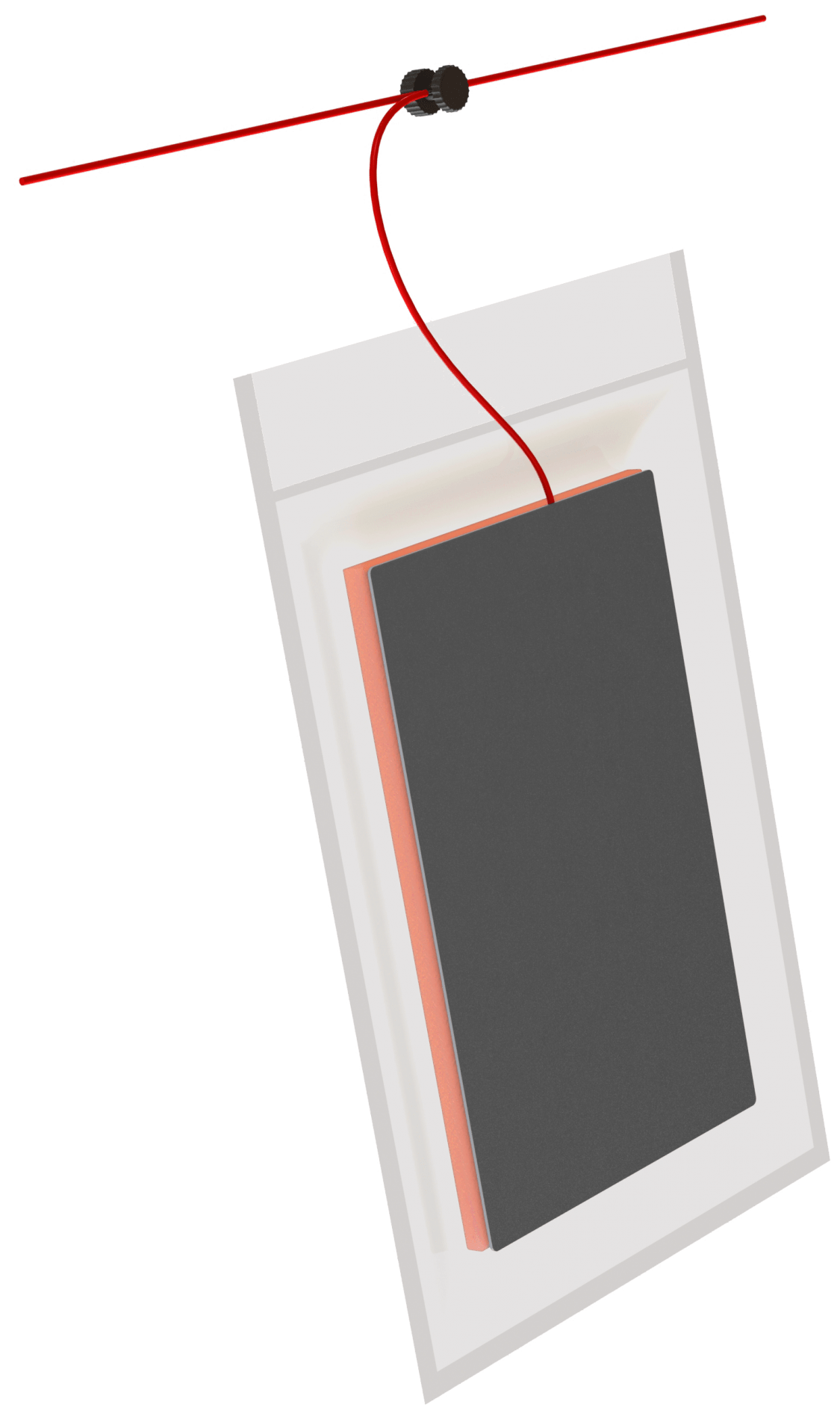

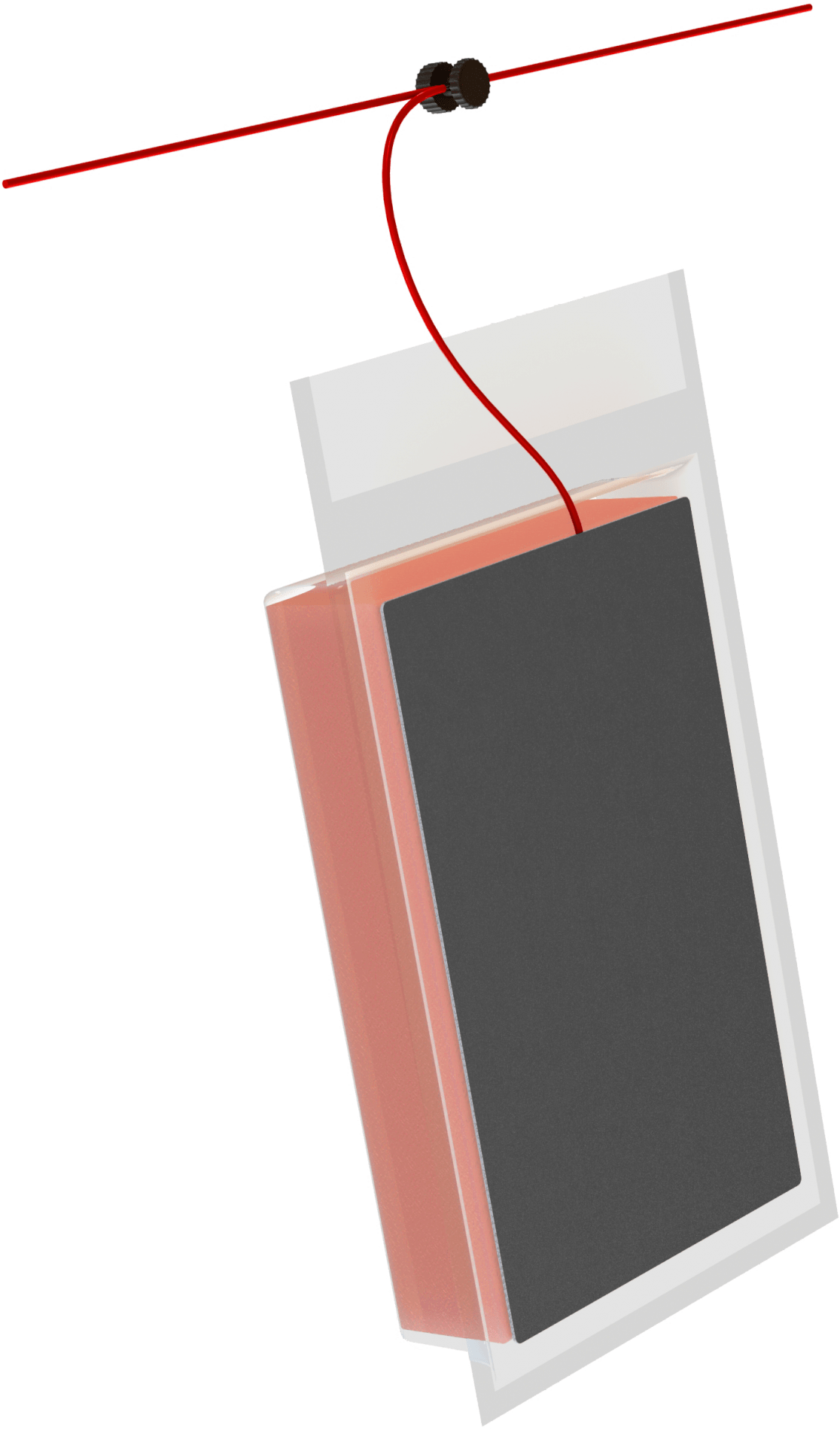

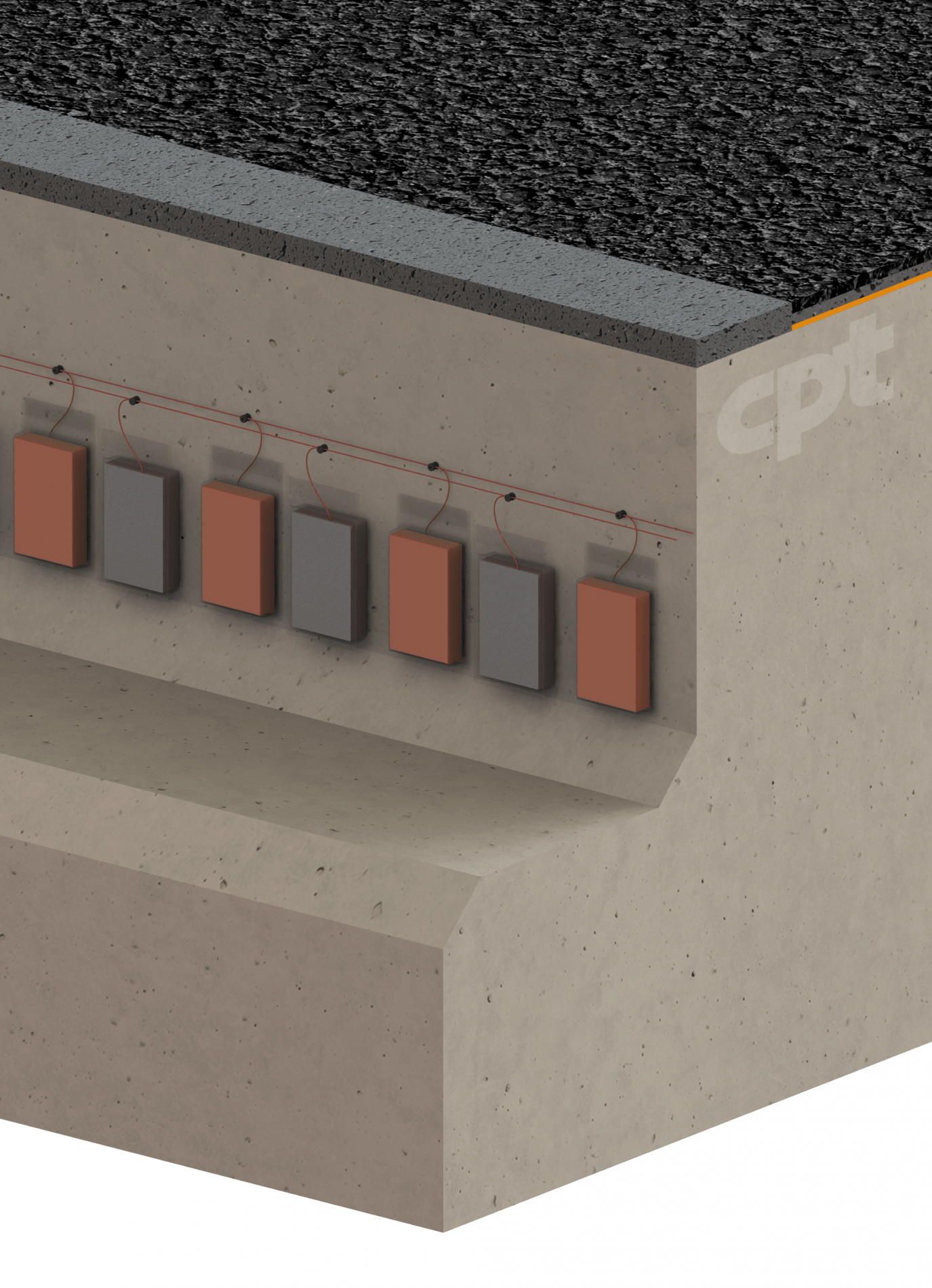

ProtectorJoint™ anodes utilise a sacrificial metal plate on the front face and a compressed foam pad on the back contained within a vacuum-packed enclosure. When the foam pad is released it expands to hold the unit tightly in the joint, pressing the anode onto the concrete surface.

A protective current is delivered directly to the steel around the joint providing long term corrosion protection.

The standard unit size is 125mm x 200mm x 8mm. Other sizes can be fabricated on request.

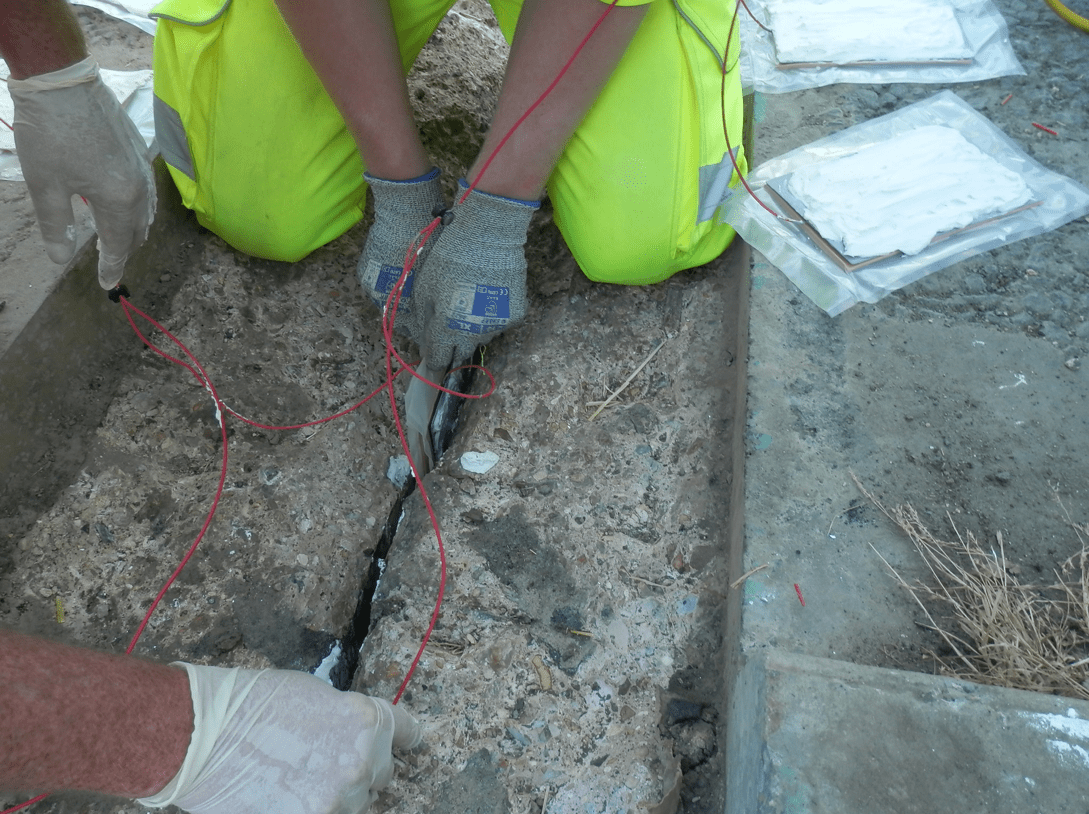

ProtectorJoint™ is designed to be installed into cleaned joints or gaps in concrete structures. Installation should be programmed to coincide with joint replacement works. The anodes are pre-connected in series to a titanium feeder wire and each anode face is coated with DuoCrete J activating adhesive.

The string of units is inserted into the joint and the vacuumpacked enclosures are punctured to allow the compressed foam backers to expand and fill the gap, holding the anodes securely in place as the joint expands and contracts.

The string of anodes can be installed to face one way only or can be placed alternate facing if both sides of the joint need to be protected. The titanium feeder wire is connected to the steel reinforcement at a convenient location e.g. at the side of the bridge. The connection to the steel can be via a surface mounted enclosure if monitoring of the system is required.

When the string of anodes is connected to the steel reinforcement, a galvanic current is generated due to the difference in potential between the anode material and the steel. The relatively large anode surface area helps to maximise current output.

The current produced will fluctuate depending on the environment. The anode material will sacrificially corrode in preference to the steel reinforcement, delivering effective corrosion control for up to 20 years.

Interconnected galvanic anode system for placement within joints

*Dependant on local conditions