Stops corrosion and extends structural life.

Our unique DuoGuard™ range of discrete anodes features DuoGuard™ is installed into concrete structures to stop reinforcing steel corrosion caused by chloride salts and carbonation. It can be used to protect contaminated but unspalled concrete saving the time and cost of replacing the concrete material. With a long system lifetime the DuoGuard™ anode provides a cost effective, maintenance free method of corrosion protection.

DuoGuard™ is not available in all regions. Contact CPT for further advice.

DuoGuard™ combats the two main types of corrosion found in reinforced concrete structures.

Carbonation induced – exposure to atmospheric carbon dioxide combined with prolonged contact to sufficient moisture and oxygen can leave steel vulnerable to corrosion.

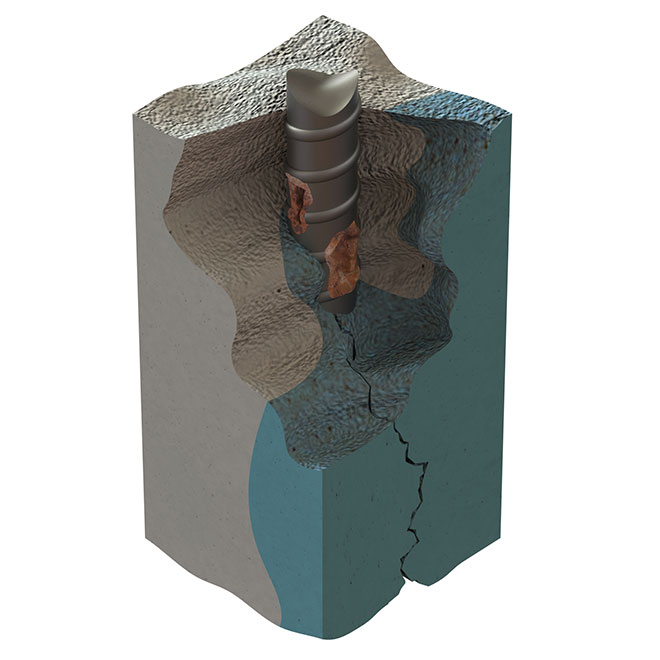

Chloride induced – if chloride in the form of inherently mixed set accelerators or external aggressive salts permeates reinforced concrete in sufficient quantities, an aggressive form of corrosion can be initiated.

When either or both of these take hold in a structure, this can lead to the concrete cracking and being displaced as the steel reinforcement expands and pushes out. The corrosion and its effects often propagate very quickly – so it is crucial to be proactive in assessing and fixing the issue.

CPT DuoGuard™ anodes feature new generation electro-chemical technology to stop reinforcing steel corrosion caused by chloride salts and carbonation for up to 50 years.

The full package: CPT also supplies all the ancillary materials needed for DuoGuard™ installation, including wires, connectors and embedding mortar.

Anodes are available in 5 sizes to suit any structure:

DuoGuard™ 175: 42 mm long x 18 mm diameter

DuoGuard™ 350: 77 mm long x 18 mm diameter

DuoGuard™ 500: 110 mm long x 18 mm diameter

DuoGuard™ 750: 165 mm long x 18 mm diameter

DuoGuard™ 1000: 220 mm long x 18 mm diameter

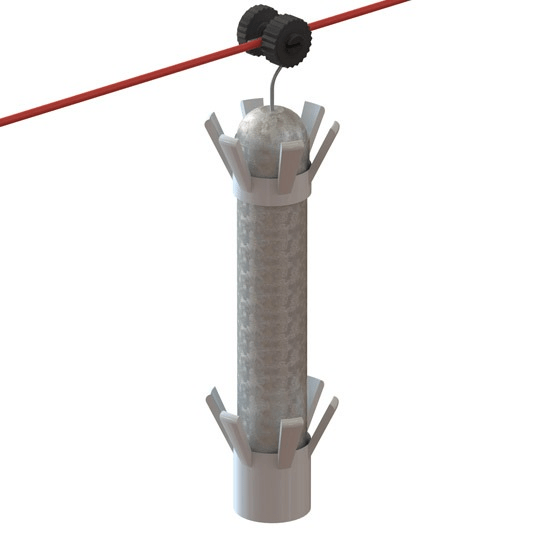

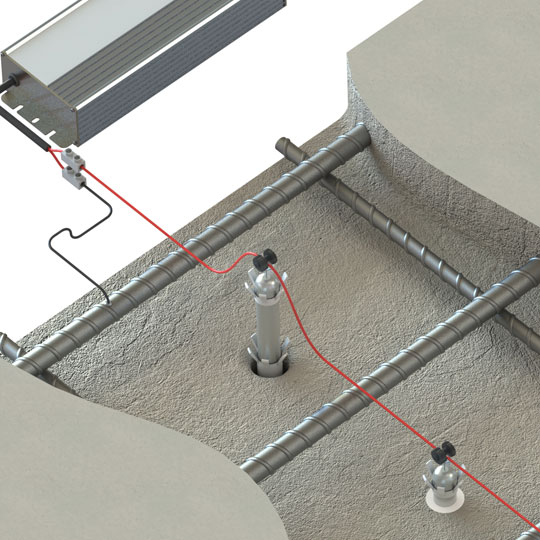

DuoGuard™ anodes are installed into contaminated areas of reinforced concrete, identified as being at risk of corrosion, by simply drilling 30mm diameter holes and embedding the anodes in DuoCrete SD mortar. These are then temporarily connected in groups to a power supply using titanium wire – just a couple of connections are required for a circuit of up to 200 anodes. The system is discrete with no surface wiring or permanent control systems – totally vandal proof.

DuoGuard™ is a hybrid treatment. During treatment a sacrificial anode is used as both an impressed current and galvanic anode. Initially, a constant voltage power supply is used to drive a high current from the installed anode to re-passivate the corroding steel, typically for one week. The same anode is then connected directly to the steel to provide maintenance free cathodic protection by means of a galvanic current. The hybrid system means that the requirement for a permanent power supply is eliminated and DuoGuard offers the advantages of a galvanic anode system, requiring little to no maintenance. The system can be designed to meet BS EN ISO 12696:2016 the international standard for cathodic protection.

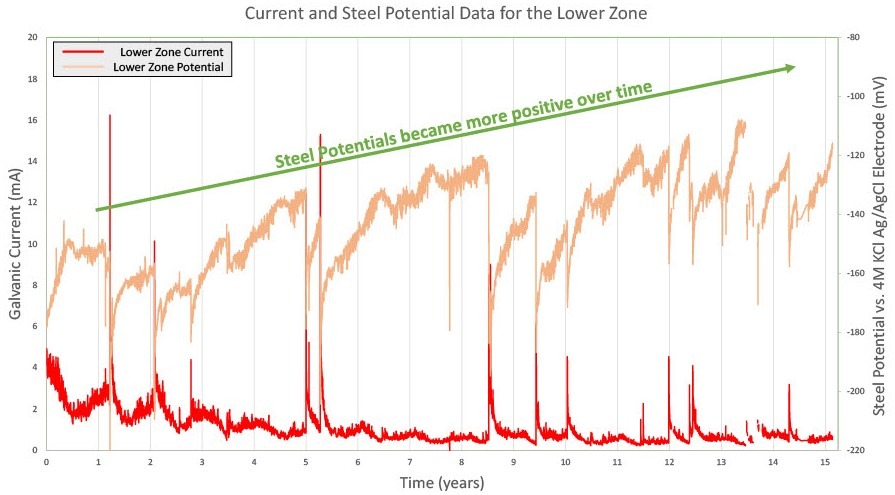

The graph below shows the protective current produced by a zone of eight anodes over a 15 year period at Whiteadder Bridge. This bridge spans a flood plain and DuoGuard™ hybrid anodes were installed into the bridge piers to control corrosion back in April 2007. The anodes can be seen to be extremely reactive to local conditions with peaks in current output coinciding with river floods and soaking of the bridge piers. During drier times the current is reduced and anode life is preserved. Corrosion rate measurements have been independently taken by Aecom and these demonstrate that the steel has remained passive throughout the monitored period as defined by the international standard for cathodic protection of steel in concrete BS EN ISO 12696:2016. Whiteadder Bridge is one of many sites where long term performance has been monitored, providing reassurance that the DuoGuard™ system will provide reliable, self-regulating, maintenance free protection.

Interconnected hybrid anode system

*dependant on local site conditions and anode size