The Harland and Wolff Dry Dock (known as the Belfast Dry Dock) was constructed between 1965-68 by Charles Brand and Sons to a design by Rendel, Palmer and Tritton. It is 1150 feet long by 160 feet wide and, when constructed, was one of the five largest docks in the world.

Location

Client

Completed

Structure

Belfast dry dock galleries were suffering from steel reinforcement corrosion due to exposure to chloride contamination from seawater.

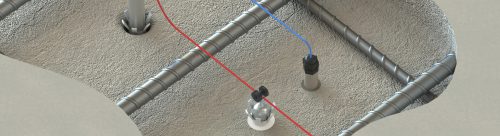

CPT designed a DuoGuard™ hybrid anode system to stop ongoing corrosion and prevent further damage at the dock. DuoGuard 500 anodes were installed into the gallery area of the structure. Using an external power source, an impressed current was applied to stop active corrosion and render the steel passive. The DuoGuard anodes were then disconnected from the power source to self-generate a galvanic current, sufficient to maintain steel passivity and control corrosion.

To allow ongoing measurement of the corrosion control, the system was monitored using CPT’s MN15 Reference Electrodes and CR1000 Datalogger, powered by an 18 watt solar panel.

The two biggest challenges on the project were working to the strict timescales and requirements set out by Harland & Wolff and seawater flooding of the galleries during the anode installation. The DuoGuard hybrid anodes were selected due to the speed and simplicity of installation, the supporting technical data and technical support offered by CPT and minimal maintenance requirements.

Corrosion related deterioration of the Belfast Dry Dock has been halted. After the initial power up period using an external power source the DuoGuard system is self-powered thus minimising future maintenance requirements and associated life costs.

DuoGuard™ Hybrid Anode halts reinforced concrete corrosion for targeted protection.

Find out more

MN15 Reference Electrode, Manganese Oxide electrode for monitoring structures.

Find out moreFor assistance and guidance from the industry experts please leave your details below and we’ll be in touch.