PatchGuard™ Strip can be installed into slots in the concrete cover zone, or into bedding joints, and is ideal for the protection of embedded steel beams or congested areas of reinforcement.

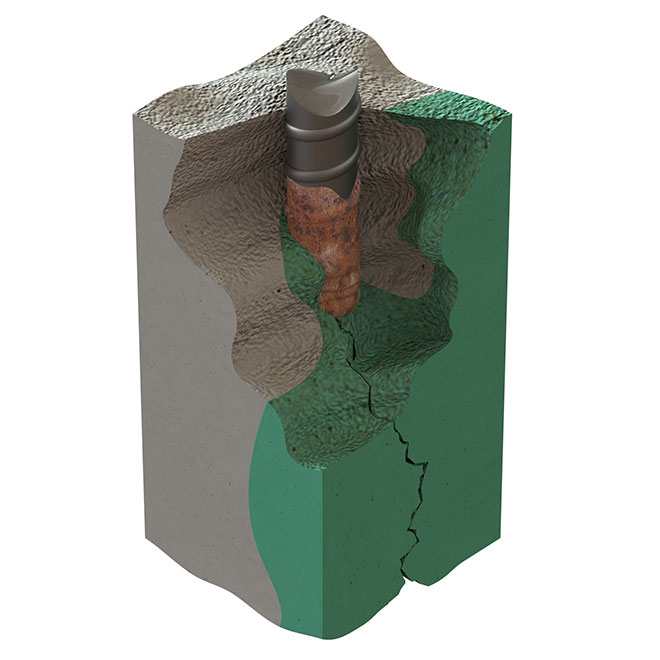

PatchGuard™ Strip combats the two main types of corrosion found in reinforced concrete structures Carbonation induced – exposure to atmospheric carbon dioxide combined with prolonged contact to sufficient moisture and oxygen can leave steel vulnerable to corrosion.

Chloride induced – if chloride in the form of inherently mixed set accelerators or external aggressive salts permeates reinforced concrete in sufficient quantities, an aggressive form of corrosion can be initiated.

When either or both take hold in a structure, this can lead to the concrete cracking and being displaced as the steel reinforcement expands. The corrosion and its effects often propagate very quickly, so it is crucial to be proactive in assessing and fixing the issue to protect the structure and maintain its asset value.

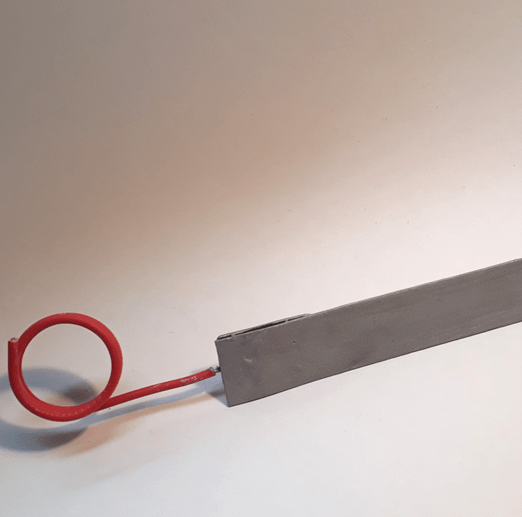

PatchGuard™ Strip is used to control corrosion and mitigate cracking and spalling in sound but contaminated reinforced concrete where a corrosion risk has been identified. The corrosion control system comprises zinc alloy strips with integral titanium connecting wires and a specially formulated backfill mortar. PatchGuard™ Strip can be supplied as individual units or pre-connected in strings of up to 20 units. When installed into slots the units will corrode sacrificially to the surrounding steel reinforcement.

The full package: CPT supplies all the ancillary materials needed for PatchGuard™ Strip installation, including connectors and embedding mortar.

Anodes are available in 2 standard sizes:

PatchGuard™ Strip: 200 mm long x 20mm wide x 3.5mm thick

PatchGuard™ Strip: 550 mm long x 20mm wide x 3.5mm thick

Other sizes can be fabricated on request.

PatchGuard™ Strip anodes are installed into contaminated areas of reinforced concrete, identified as being at risk of corrosion by simply preparing 6mm wide saw cuts and embedding the anodes in DuoCrete™ PG mortar.

The PatchGuard™ Strip system is connected in strings of up to 20 anodes using recessed titanium wire connected at each end to the reinforcing steel. The system is discrete with no surface wiring or permanent control systems and is totally vandal proof.

PatchGuard™ Strip anodes are a purely galvanic cathodic protection system. The galvanic (or sacrificial) anodes act by corroding favourably to the steel, reacting to corrosion threats whilst supplying a protective current that counters the initiation of corrosion. Corrosion of the anode is non-expansive and does not negatively impact the structure. PatchGuard™ Strip technology is a long-term low maintenance solution.