It is widely understood that the use of galvanic anodes within concrete patch repairs can extend repair life and prevent adjacent corrosion initiation when the surrounding concrete is contaminated with chlorides. A further sign of the acceptance of galvanic anode technology is the publication of the latest Design Manual for Roads and Bridges (DMRB). The DMRB incorporates the Manual of Contract Documents for Highway Works (MCHW) which includes Specification Series 5700 and, in particular, Clause 5712 – a standard specification for the use of galvanic anodes within patch repairs. This long-awaited update removes the requirement for highways engineers to prepare a Departure from Standard prior to specifying galvanic anodes.

The Design Manual for Roads and Bridges also incorporates Standard for Civils Work CS462 which spells out the options for dealing with sound but chloride contaminated concrete when carrying out patch repairs to concrete bridge structures: leave in place and continue to monitor, remove the contaminated concrete, install an impressed current cathodic protection system or incorporate galvanic anodes into patch repairs to prevent corrosion initiation and associated concrete spalling around the repair boundary. In many cases chloride contamination is localised and may be isolated to areas of low cover, splash zones or joints. In such cases impressed current cathodic protection may be considered a disproportionate response with high initial costs and burdensome on-going maintenance requirements. Breaking out all contaminated concrete can also prove to be expensive and disruptive, especially if propping is required. In contrast, the inclusion of galvanic anodes into patch repairs is quick, inexpensive and maintenance free.

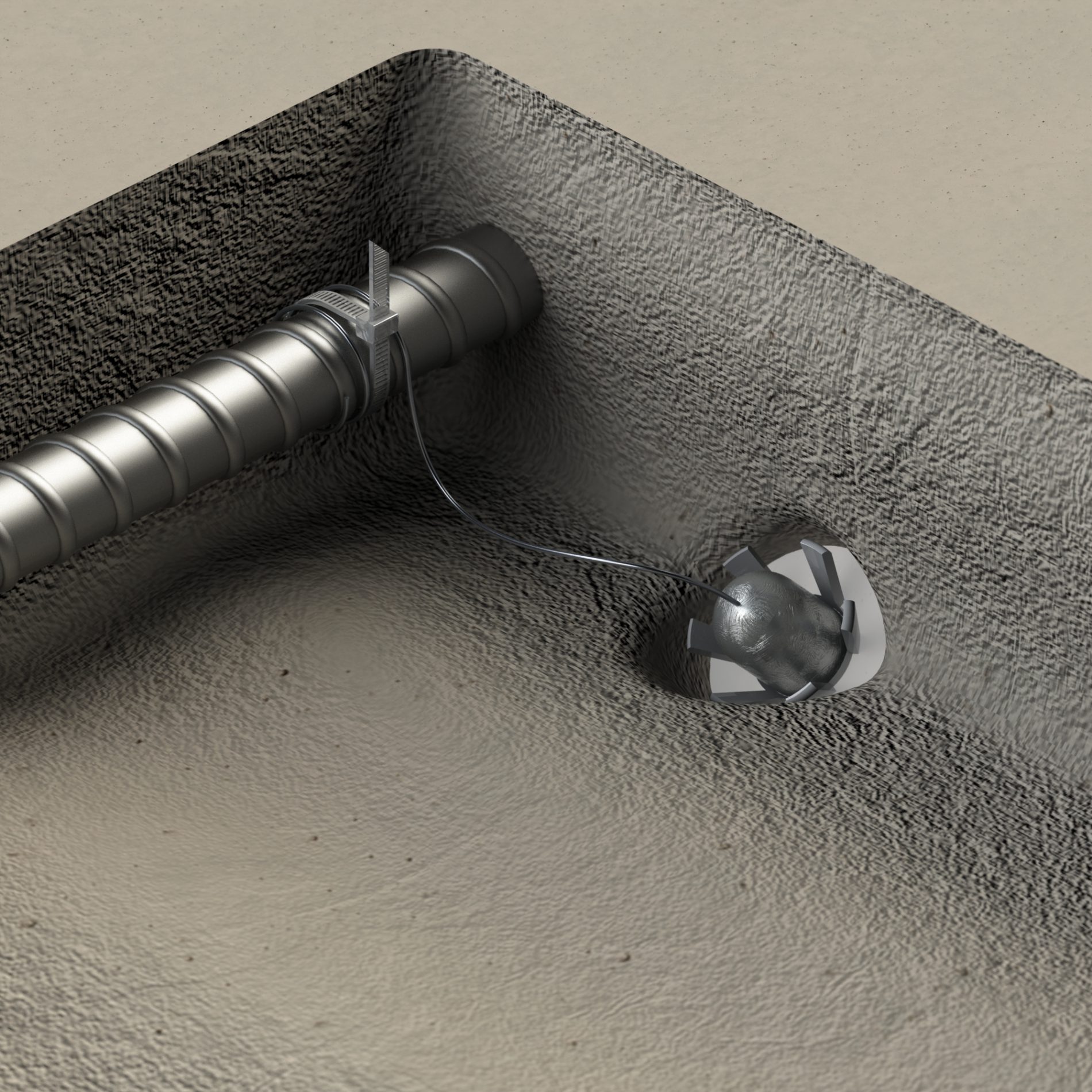

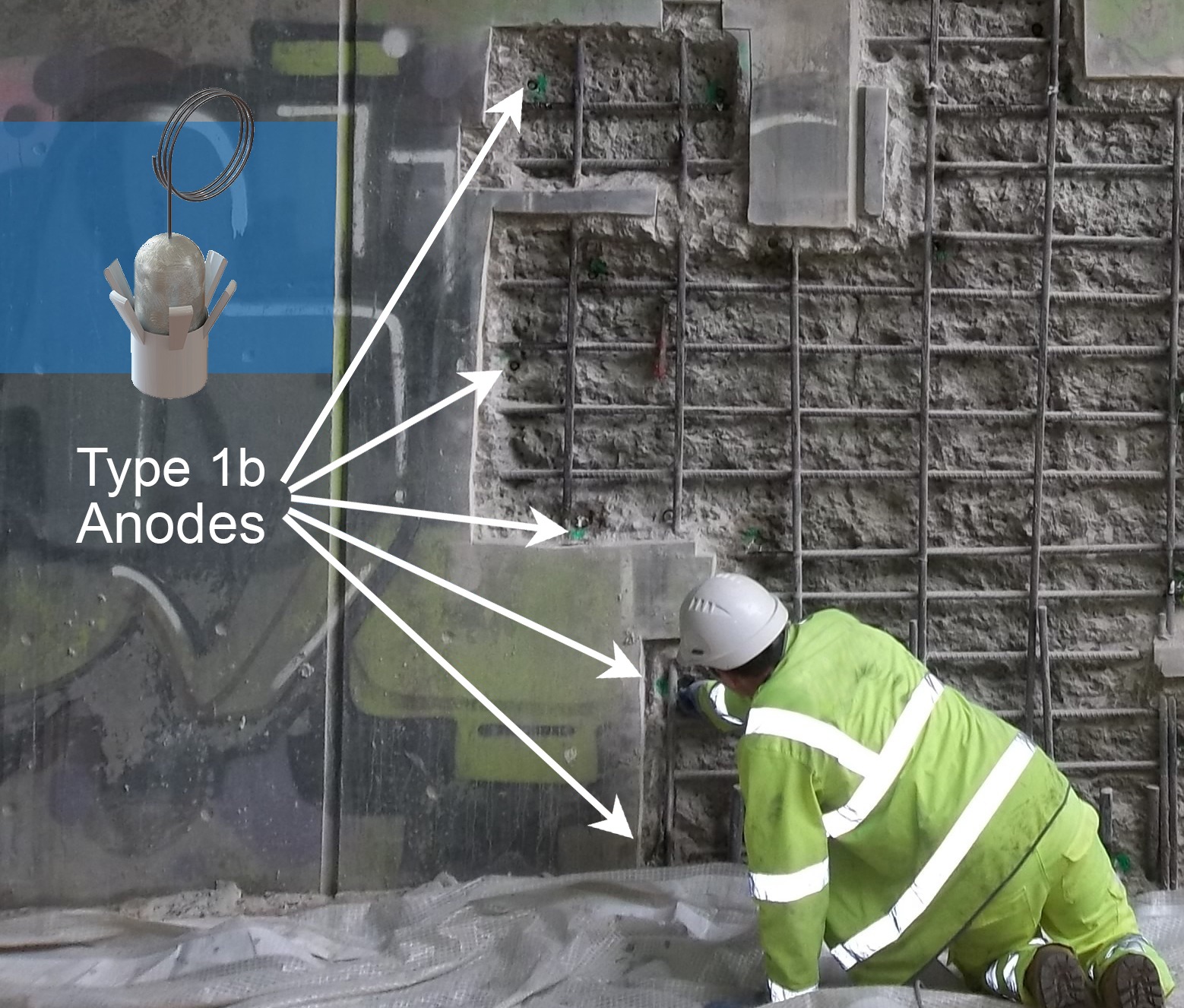

CPT PatchGuard galvanic anodes are described as ‘Type 1b’ in Specification Series 5700 Clause 5712. Type 1b anodes are grouted into small drilled holes around the inside boundary of patch repairs so that the anode is located within the contaminated concrete around the patch. In contrast, ‘Type 1a’ anodes are tied directly to the exposed steel in the broken-out area and end up being embedded within the patch repair material. Independent research by Loughborough University, ‘Site performance of galvanic anodes in concrete repairs’, demonstrated that Type 1b anodes have a more significant, and longer lasting, polarising effect on the reinforcing steel around the patch repair than Type 1a anodes. This is because Type 1b anodes are located in a lower resistivity environment within the host concrete and closer to the steel requiring protection. Because they are installed into drilled holes, Type 1b anodes are also more able to protect inaccessible steel such as that typically found around half joints.

Many Highways England structures are already benefitting from PatchGuard protection, having been specified through the Departure from Standard procedure, or by use of a draft version of clause 5712. Recent projects include Windsor Road Bridge on the M4 and Portbury Railway Tunnel on the M5. Contact CPT for further details.

Those with responsibility for managing highway structures can now quickly specify galvanic anode patch repair protection by incorporating Clause 5712 from the Manual of Contract Documents. DMRB, CS462 and MCHW Series 5700 are also approved by the devolved administrations in Scotland, Wales and Northern Ireland.

CPT’s technical team are on hand to offer advice and assistance including a BS EN 15257:2017 Level 4 cathodic protection design service. Use the form below to contact the team with any questions.

Share this article: