Lilley Bottom Bridge was constructed circa 1972 as part of the Lilley Bypass works. The structure comprises a carriageway and two footpaths over the A505 near Lilley.

Location

Client

Completed

Structure

The structure incorporates a central deck section supported on half joints on cantilevered extensions to the side spans.

The existing expansion joints had deteriorated leading to water ingress and a risk of chloride induced corrosion of the congested steel reinforcement deep within the joint.

As the expansion joints were due to be replaced the opportunity was taken to install the ProtectorJoint™ system inside the joint cavity whilst access was available.

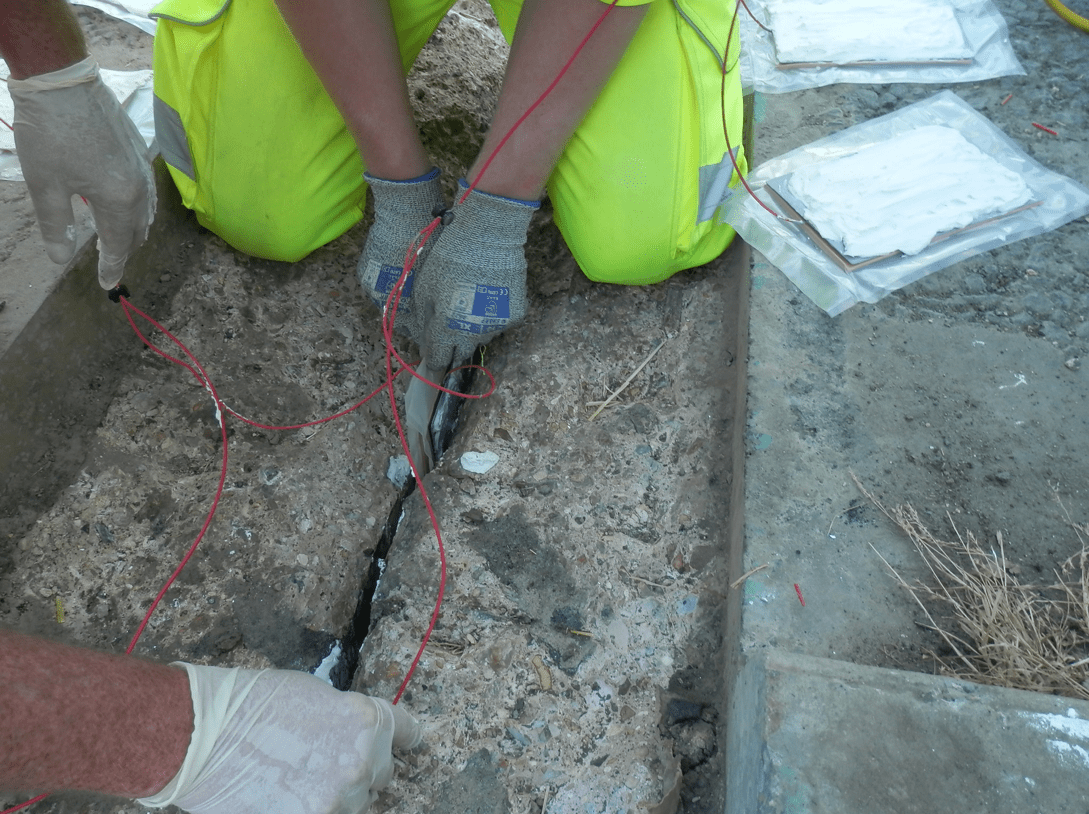

The ProtectorJoint™ anodes were pre-connected and installed at 400mm centres. The anode features a galvanic plate on one face and a compressed foam pad on the back which, when released, presses the anode onto the concrete surface and holds it securely as the joint expands and contracts. The anode material will sacrificially corrode in preference to the surrounding steel reinforcement.

The string of anodes was connected to the steel reinforcement via a surface mounted connection box, located at the side of the bridge, where measurements can be taken to monitor system performance.

The risk of corrosion related deterioration around the expansion joints at Lilley Bottom Bridge has been mitigated.

The simplicity and speed of installation meant that the ProtectorJoint anodes could be installed into two bridge joints during a single night closure

The ProtectorJoint™ system is self-powered thus minimising future maintenance requirements and associated life costs. The ProtectorJoint™ system will provide effective corrosion control for a life of up 20 years.